-

-

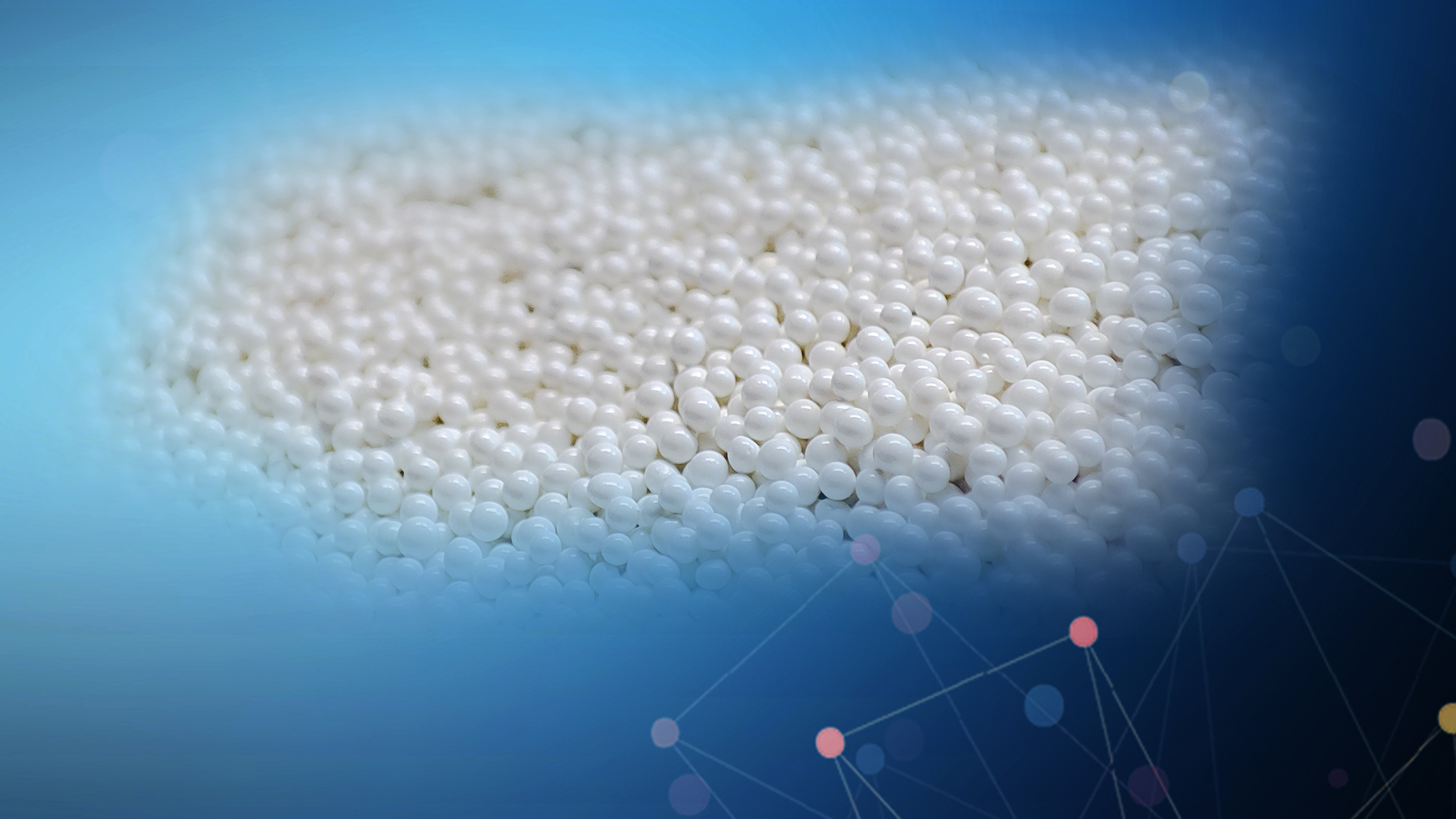

Ceramic Performance Parameters· Sintering temperature: 1650°C· Molding pressure: Dry pressing: 100MPaIsostatic pressing: 180MPa· Sintering density: 3.85g/cm³· Shrinkage rate: 14.7%Physical and Chemical Parameters· Original crystal particle size: 2μm· Average granulation particle size: 100µm· Bulk de...

-

-

-

Shot peening is a crucial metal part processing technology that can effectively extend the fatigue life of parts. The basic principles of shot peening are elaborated from six aspects as follows.Cyclic LoadA cyclic load refers to a load whose magnitude and direction change periodically or vary random...

-

HISTORY OF NABALTEC – A success story1994 | Founding of Nabaltec GmbHThe company focused on the processing and refining of aluminum hydroxide, aluminum oxide and other mineral raw materials into high-quality special products.1995 | Spin-off from the VAW group and sale to the Ambe...

-

Time: March 10th - 12th, 2025Venue: Shanghai World Expo Exhibition & Convention CenterBooth: Booth E823, Hall H2

-

Thanks to every friend who has accompanied Fine-tech's growth. It is your support and trust that have made every day of ours meaningful. On this Lantern Festival, may our gathering become a part of your wonderful memories. We also look forward to the days to come, hoping that Huntae can continue...

-

According to the data of the online query platform of the General Administration of Customs, China's imports of alumina (alumina, but not artificial corundum) in August were 156,817.64 tons, a decrease of 0.73% from the previous month and a decrease of 60.22% year-on-year. Among them, Australia ...

-

SMM July 20 news: At the 17th SMM International Aluminum Summit - Electrolytic Aluminum and Raw Materials Forum, SMM senior analyst Tian Chen analyzed the operation of the global alumina industry and the future market outlook.SMM believes that due to the continuation of the pattern of weak external ...